WHAT IS PLASMA CUTTING ?

Plasma Cutting is a profile cutting technique that can cut through any conductive metal, such as steel, stainless steel, aluminum, brass, titanium, and copper. The thickness of the material depends on the power of the plasma cutter that you are using as well as the cutting parameters that you choose.

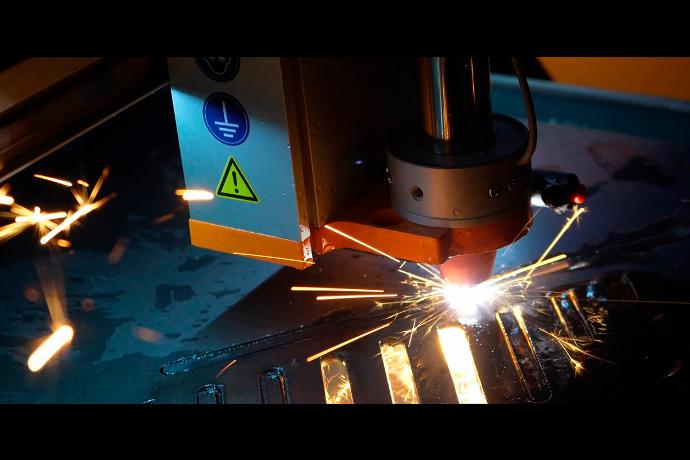

Plasma Cutting is a melting process in which a jet of ionized gas at temperatures exceeding 35,000°F is used to melt and expel material from the cut. Throughout this process, an electric arc is struck between an electrode in the cutting torch and the workpiece which is grounded to the plasma cutter. Compressed air is the commonly used gas that when combined with the electric arc forms the fourth state of matter called plasma. The plasma is pushed through a small hole in the nozzle at the tip of the cutting torch creating a pressurized plasma jet that melts away the material as the machine moves the torch along your cutting profile.

Plasma cutters come in all shapes, sizes, and price ranges. Inexpensive plasma cutters come with a handheld torch that allows you to manually cut through your materials. When installed on a CNC machine, a special long cylindrical torch is used and is mounted to the movable gantry on the machine. Rather than using a trigger like a hand torch to start the plasma arc flowing, a signal from the CNC machine is used.

CNC PLASMA CUTTING

Manual plasma cutting requires a very steady hand and a high skill level in order to make clean and accurate cuts, especially on very complex geometry. It is next to impossible to replicate machine-quality parts with high repeatability. Installing a plasma cutter onto a CNC (computer numerically controlled) machine takes the human out of the equation and allows for fast, smooth, and high-quality parts that can be reproduced with incredible accuracy.

The process of CNC plasma cutting is similar to that of a CNC router or milling. Everything starts with a design that can come from your favorite vector-based CAD or drawing program. Your design is then brought into CAM software (such as Sheetcam) where you tell the CNC how you want to cut out your parts along your vector lines as well as how fast you wish to move the torch through the material. This CAM software will create a program that the CNC can understand called "G Code". The CNC's controller software reads this G Code file and translates it to move the machine executing the desired cuts.

Due to a lot of factors, CNC plasma cutting was typically only used in commercial or industrial environments. But with the costs coming down on plasma cutter units as well as the flexibility offered in CNC machines, like the STEPCRAFT M-Series line, you can now add CNC plasma cutting affordability to your home or business workshop.

THE STEPCRAFT CUT 50 PLASMA CUTTER SYSTEM

With over 15,000 + CNC systems installed around the world, it stood to reason that some STEPCRAFT customers would ask about cutting ferrous materials like steel and stainless steel with their CNC System. Our engineering team went to work and created a new CNC Tool that can be quickly added to any STEPCRAFT M-Series CNC System, giving you the ability to turn your machine into a full-functioning CNC Plasma Cutter.

As with the many other CNC attachments that are offered to expand the functionality of the STEPCRAFT CNC systems, the Cut 50 Plasma Cutter can be quickly added and removed from your M-Series machine and when it is in use, it seamlessly integrates into the machines electrical and software systems providing ease of use with tons of capability.

The Cut 50 Plasma Cutting System includes everything you need to get started right away. A powerful 50-amp IGBT plasma cutter with a CNC torch is included and gives the capability to cut through materials measuring up to 5/8" thick. To provide material touch-off sensing as well as crash detection, a specially designed torch holder integrates into the 43mm tool holder on the gantry and is electrically connected to the control module interface. To keep your material cool and prevent excessive warping, a water table is included with replaceable slats to support your workpiece. The water table also serves to reduce the smoke and dust that can become airborne in your shop. Sheetcam software is also included allowing you to quickly program all of your plasma jobs. And finally, we even include a spare set of consumables to keep you running job after job.

ADD A PLASMA CUTTING SYSTEM TO YOUR M-SERIES CNC TODAY!

We have complete system packages for the M.1000, M.700 and M.500 CNC machines.