MILLING PARAMETERS

vc = Cutting speed (m/min)

d = Tool diameter in millimeters (mm)

z = Number of teeth

fz = Tooth feed (mm/tooth)

vf = Feed rate (mm/min)

PDF DOWNLOAD

The end mill speed is calculated with the following formula:

n [rpm] = (vc [m/min] *1000) / 3.14 * ø d1 [mm])

Example calculation:

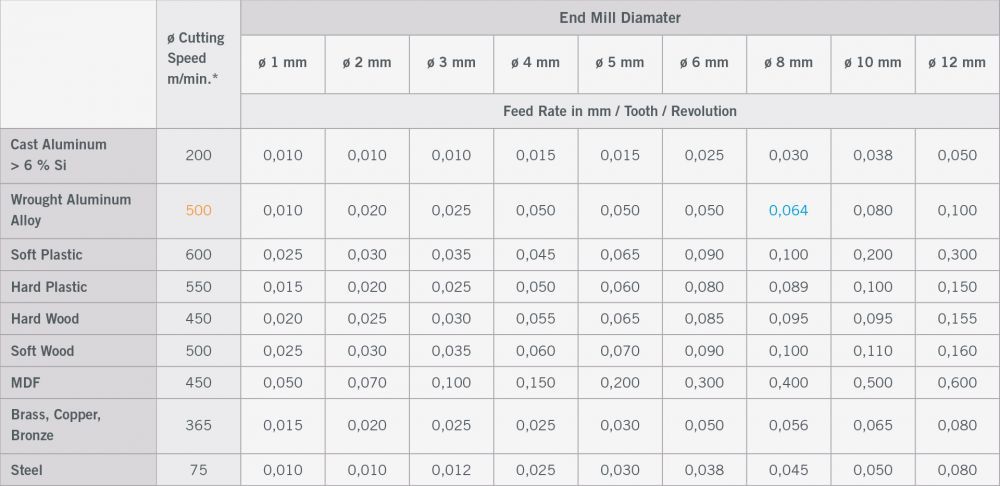

vc = 500 m/min (selected from chart)

d = ø 8 mm

19904 rpm = (500 *1000) / (3.14 * 8)

If the maximum speed of the milling motor is lower than the calculated value, the maximum speed of the milling motor needs to be inserted into the formula for the feed calculation.

The end mill feed rate is calculated with the following formula:

vf = n * z * fz

Example calculation for aluminum (wrought alloy) with 8 mm end mill 2-flute:

n = 15923 rpm from upper formula

fz = 0,064 from chart

z = 2

2547,77 mm/min = 19904 * 2 * 0,064

BENCHMARK FOR SPEED AND FEED

* The stated cutting speeds are average values. In result of the milling process and the type of end mill adjustments might be necessary . Roughing: Reduction of up to 25 % – Finishing: Increase of up to 25 % – HSS end mill: Reduction of up to 50 % (hard materials) – VHM end mill: Increase of up to 25 %

COOLING / LUBRICATING

The cooling of non-ferrous metals occurs in best case with a lubrication system in combination with lubricant. Furthermore the lubricating improves the surface quality and the service life of the tool. Lubricating with soap solution is suitable on acrylic glass. This improves an excellent surface.

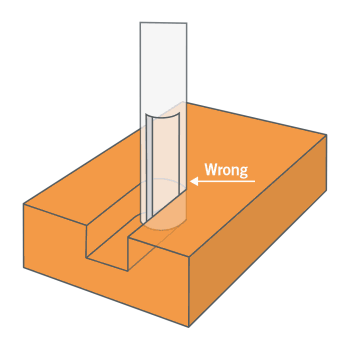

DOWNCUT MILLING

In downcut milling, the end mill pulls itself into the workpiece, which can lead to the gantry or the Z-axis beeing pulled uncontrolled (backlash of lead screw) in the direction of the workpiece during the removal of larger chips. This causes a less precise milling pattern and can even result in the breakage of the end mill, if the chip building is too large.

Assuming backlash-free ball screws are used, the downcut is preferred over the upcut milling.

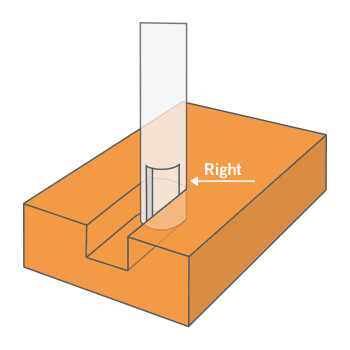

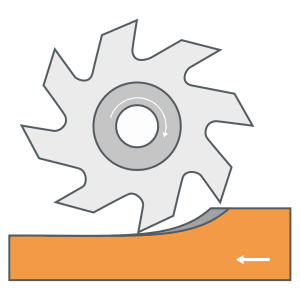

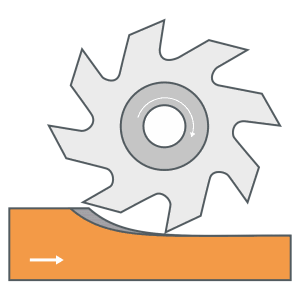

UPCUT MILLING

During upcut milling, the end mill pushes away from the workpiece, which, when only removing little chips, quickly causes the cutting edge to push out of the workpiece. This leads to chatter marks which create an unclean surface and reduce the endurance of the end mill.

The upcut milling is favored on machines with threaded lead screws which contain backlash.

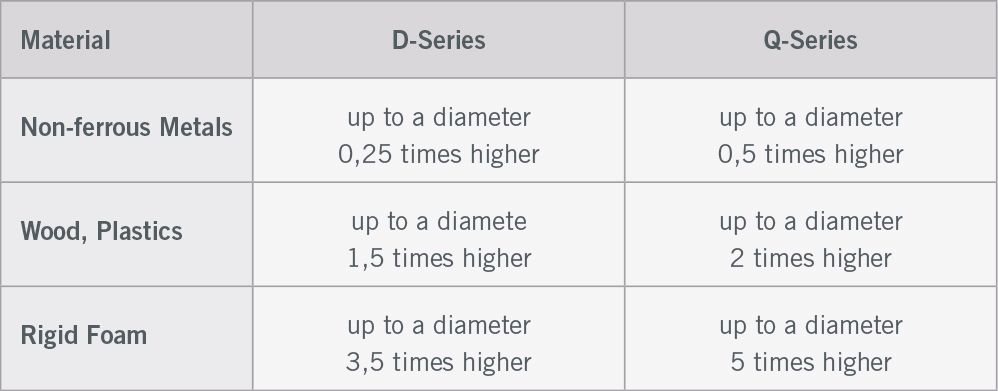

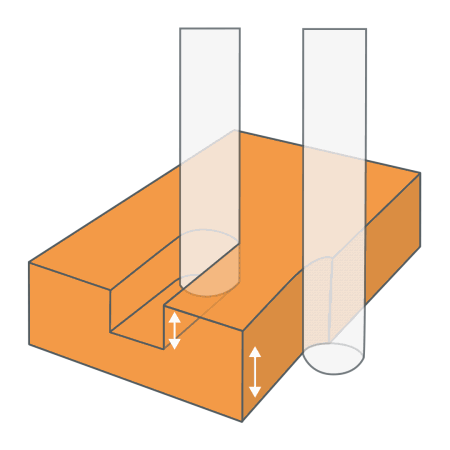

RELIEF-GRINDED END MILLS

The maximum possible infeed is usually reduced to the spiral length of the end mill, otherwise the shank will rub on the workpiece. Due to the relief-grinded shank, depths over several infeeds up to the maximum effective lengths are possible, thus, exceeding the spiral length.

.png)

LUBRICATION SYSTEM 20-50 ML/H

increasing lube

Dependence of lubrication system on production process

Milling

Drilling

Grinding

Lapping

Turning

Grating

Honing

increasing material qualification

Suitability of lubrication system for cutting materials

Cu Alloy

Al Casting Alloy

Steel ferritic

Mg Alloy

Wrought Aluminum Alloy

Pearlitic

Cast Iron

Stainless Steels